The Growing Importance of CNC Machining in Manufacturing

The Growing Importance of CNC Machining in Manufacturing

Blog Article

The Growing Importance of CNC Machining in Manufacturing

- Source: tensilemillcnc.com

Imagine a scenario where all the complex structures are assembled manually. Well, it surely gives an artistic touch, but think about the time consumed. Will it even be possible? The world has seen drastic technological development over the years. Thanks to CNC machining, tasks that were deemed impossible can be easily manufactured. It is one of the most effective manufacturing equipment available. Interestingly, at some point, we all used to watch YouTube videos of machines assembling phones or routers while having our meals. We just didn’t realize that back then.

This article will discuss this interesting tech stuff, CNC machining, and explain its significance, pros, and cons, along with a few examples.

What Are CNC Machines?

The term CNC stands for Computer Numerical Control, which is about the computerized operation of machining gear used in the manufacturing industry. To put it simply, you can cut heavy metals or assemble complex systems with the help of computers. These machines don’t work manually, like a lever or a wheel. Instead, they function using CNC machining language like G-Code or M-Code. These codes give the machines accurate measurements to get precise results.

CNC equipment is designed to operate with various materials, including metals, alloys, wood, and more. The size of the equipment can vary depending on the specific part being created, making it adaptable to different manufacturing needs. Since CNC machines are computer-controlled, they offer impressive precision, efficiency, and versatility. Due to their ability to process complicated designs, many industries are opting for CNC tools for various applications to deliver top-grade output.

Why CNC Machines Are Important?

There were days when handling heavy machinery was a challenging job. From the precision aspect, there is scope for error in handling machinery manually. The world is on a spree of constant evolution, and the need for CNC machining has never been more prominent. Many industries are coming up with new-age structures that require an extra hand to give out an impeccable output. CNC machines offer precise, accurate production by programming exact specifications, ensuring consistent quality with precise measurements.

The manufacturing industry has become more consistent, reduced waste, and ensured minimal human error by using computer-aided manufacturing (CAM) and computer-aided design (CAD) software. In addition to this, CNC machines provide flexible manufacturing, low maintenance, and design retention, along with the ability to handle complicated designs with precision. Inclining on this technology helps industries by speeding up production and lowering energy consumption.

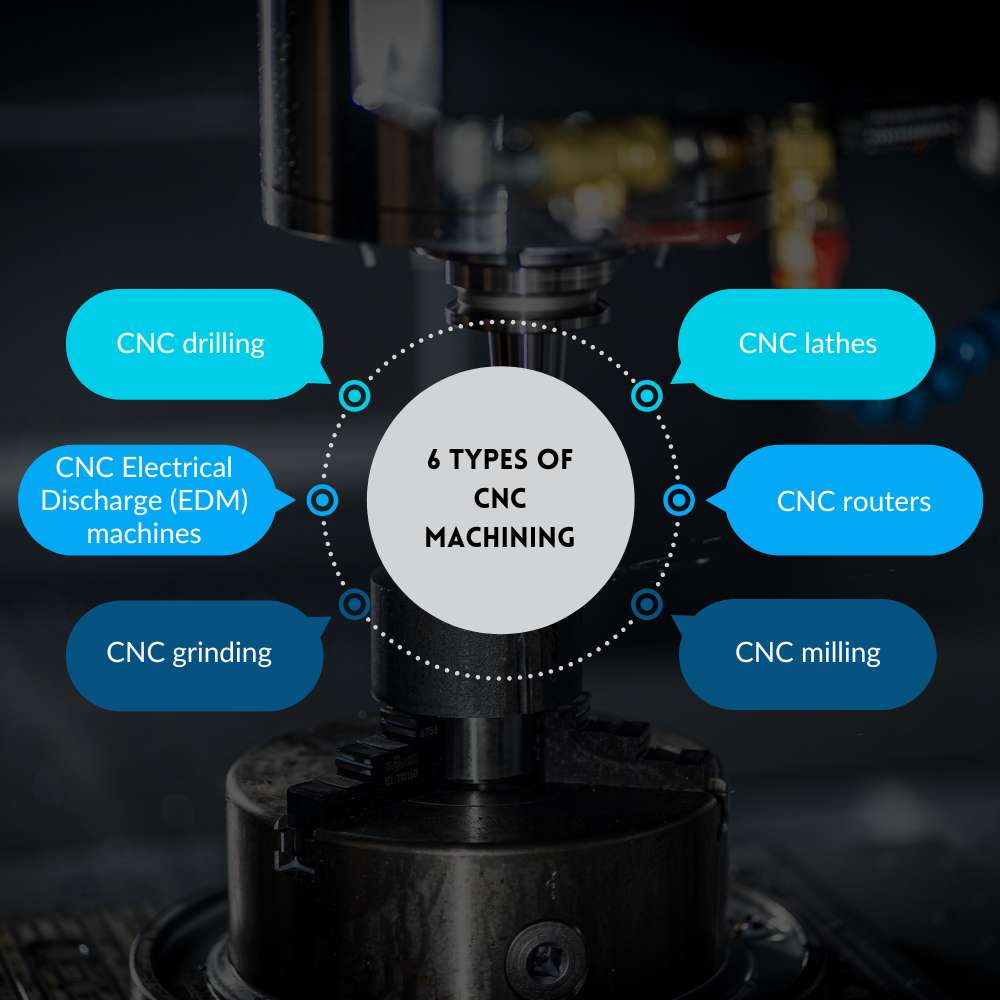

6 Types of CNC Machining

- CNC lathes

- CNC routers

- CNC milling

- CNC drilling

- CNC Electrical Discharge (EDM) machines

- CNC grinding

What Are The Advantages of CNC Machining?

1. Highly Precise and No Errors

One of the major advantages of CNC machines is their high precision and definiteness. Because these machines are controlled by computers, they can be very accurate. With this level of precision, industries can create complex machinery that requires exact measurements.

2. Extreme Capability

Unlike traditional machining, CNC machining uses far more versatile methods. It can easily create complex shapes, detailed contours, and smooth finishes with advanced technology. Currently, it is challenging to achieve this manually.

3. Faster and Effective Production

What many industries struggle with is the efficiency of production. Every manufacturing unit wants to get their desired product accurately. That can be achieved smoothly with the help of CNC machines. These machines produce products more swiftly and efficiently than traditional machines. Without any human involvement, CNC tools can easily perform tasks like loading raw metals and unloading finished products. This feature results in high productivity and cost savings.

4. Faster Assembly

One of the major benefits is that the components made under CNC machining are easier to assemble. Since these machines are precise and consistent, parts fit perfectly, as they are directed in the computer. This ensures that everything functions smoothly and saves a lot of time and money.

5. Minimal Wastage

Another major plus point of CNC machining is the less amount of material wastage. As long as you design the product accurately on the computer, the machine follows the instructions perfectly, and it is less likely to make any mistakes. It handles precise cuts and angles without wasting much material, making it an efficient option for manufacturing.

6. Safer Workplace

The chances of workplace accidents are minimal because CNC machines create a safer working environment by reducing direct human involvement in the manufacturing process. Modern tools use automation, which makes them more efficient and safer to use. Just like modifying software, designs can be updated simply without direct human interaction with the machines. By minimizing direct contact with machinery, CNC technology helps make manufacturing workplaces safer and more secure for everyone involved.

7. Less Energy Consumption

CNC machines use much less power than the old machines. They work quickly and efficiently, which helps lower electricity usage. If your business is aiming to reduce the environmental impact, then CNC machining is the best option to save energy and keep it green.

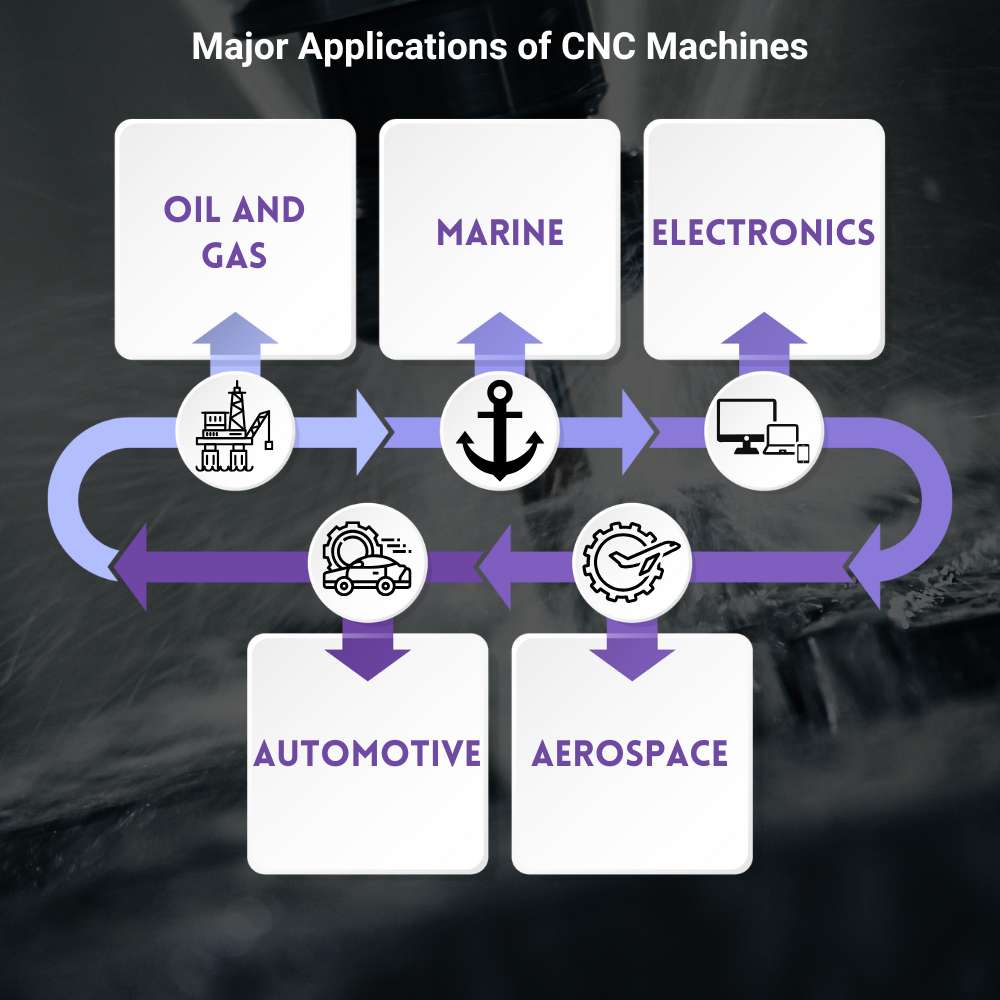

Major Applications of CNC Machines

Oil and Gas: The oil and gas industry uses CNC machining to create essential parts like valves, pumps, and drilling equipment. These components need to withstand extreme conditions, and these machines ensure they are durable with the best quality.

Marine: The Marine sector uses CNC machines to produce corrosion-resistant parts like propellers and engine components.

Electronics: In the electronics industry, CNC machines are used for manufacturing printed circuit boards (PCBs), connectors, and complex parts. The precision of CNC machines ensures that electronic devices function smoothly and consistently.

Automotive: CNC machining is the foundation of automotive manufacturing, producing everything from engine parts and transmission components to detailed designs in car interiors. It delivers both performance and style, perfect for any type.

Aerospace: Since the aviation industry requires utmost precision and reliability, CNC machines offer the best outputs. From aircraft parts like airfoils and landing gear components to other critical pieces, CNC machining ensures aviation safety and performance.

Summary

CNC machining is the process of manufacturing that functions with the help of computer programming. They revolutionized the industrial sector by producing high-level products with minimal errors. CNC machines are more efficient than manual tools. Major industries rely on these machines due to their requirement for precision, performance, quality, and safety. It is important that you choose machines that perfectly blend with your technical aspects.